Choosing the right tool for wood carving, jewellery making, or any engineering jobs are not a easy. It takes much to choose the best one. Carbide burring tool is the best tool for burring metal, wood or plastic. Additionally, it offers a real a sense perfection to operate. A tungsten carbide burr may be the choice of many. However, to know more details on carbide tungsten burrs, stick to the end want to know ,.

What exactly are TUNGSTEN CARBIDE BURRS?

Before we continue, let us review what tungsten carbide burrs are? You need to observe that carbide rotary burrs will often be known as rotary files or die grinder bits and are accustomed to cut, shape, grind and take sharp edges, burrs, and excess materials. Because of tungsten carbide’s hardness and wide range of applications, we stock these burrs in several shapes and sizes well suited for ferrous and non-ferrous metals. Burrs rotate at very fast to offer the best possible manipulation in the worked material.

CARBIDE BURRS APPLICATION:

They are utilized in a variety of industrial processes, including metalworking, tool manufacturing, engineering, model engineering, wood carving, jewellery making, welding, chamfering, casting, deburring, grinding, porting cylinder heads, and sculpting. Often, carbide burs are utilized in dental procedures such as crown preparation, aesthetic composite fabrication, endodontic access holes, and dental procedures.

In addition to being used in various industries, such as aerospace, automotive, dental, metal sculpturing, and metal smiting, they can also be located in other areas of expertise.

TYPES OF TUNGSTEN CARBIDE BURRS

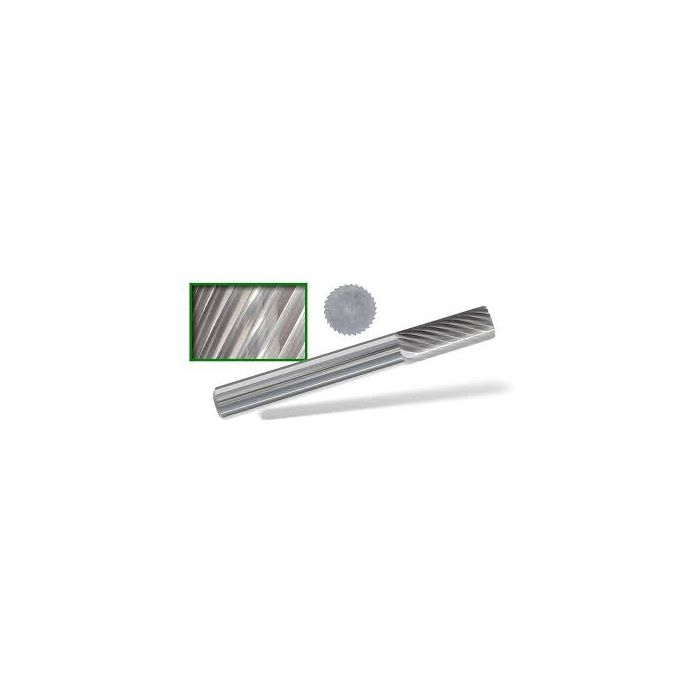

CYLINDER CARBIDE BURRS

There are several carbide burrs available today, nevertheless the cylindrical you’ve got for ages been the most common. You will find parallel sides around the end of the carbide burr, and there isn’t any cutting face on either side with this burr. An end-cut base is positioned on either sides or end of a burr cylinder. This feature offers convenience when washing the cylinder base and reaming it. Generally, these are suitable for die-grinders and small lathes with 6mm spindles. You have the accessibility of three sizes for small craft tools and eight various sizes, which drill chuck users may prefer. There is a use of three various sizes for small craft tools and eight different sizes, which drill chuck users may select. To offer the the best results using this kind of burr, the shaft of your respective instrument must be positioned as far as part of your collets as you possibly can to attenuate chatter. To lessen the vibrations a result of the pace from the drill, the harder support you can offer in your burr plus your metal, better. For example, they could be diamond or fluted.

Diamond-Cut Burrs –

Metal, steel, high carbon alloys, titanium, cobalt alloys, hardwoods, and softwoods might be worked with this manner.

Fluted Cut –

it is possible to process plastics and non-ferrous metals like aluminium, brass, and softwoods.

BULL NOSE CARBIDE BURRS

Carbide burrs are incredibly convenient when cleaning and deburring clearance holes in surfaces. Additionally, this profile can neatly down fillet joints in corners of fabrications with corner welds. Interestingly, a 3mm shank choice is readily available for tools applied to smaller craft projects.

Interestingly, it was created with tungsten carbide since the material. Stainless is also a good candidate with this tool. Many metal alloys, bronze and brass, are less corrosive and much better fitted to the ‘Non-Ferrous’ options. You can even select a spindle for usage with pillar or power drills, which may be better than some. When it comes to surface finish quality and longer tool life, these carbide burrs offer superior performance due to their special surface finish.

BALL SHAPED CARBIDE BURRS

A round or dome-shaped carbide burr is helpful for chamfering corners. Additionally, you may also begin using these screws in recesses to interact with metal about the back in the ball. Grinding and stock removal using a carbide burr are very widespread, mainly in the industrial sector.

These small burrs are particularly well matched to fine pieces of jewellery, that are usually small , detailed.

You’ll be able to apply power tools to several materials, especially hard ones like metal, ceramic, plastic, as well as wood.

Carbide burrs are available in ball-shaped shapes and can be cut universally and quickly, removing considerable amounts of fabric. The design with the ball burrs allows for a high amount of smoothness. Furthermore, fortunately they are capable to acquire a high speed along with high temperatures when employed.

SPHERICAL CARBIDE BURRS

It is rather useful to shape surfaces using a carbide bur having an oval tip, or possibly a teardrop tip, particularly if your surface is curved. It’s also worth mentioning that this method also can gain a neat job on corner fillet welds. Some tools can come with a 3mm spindle; otherwise, most die grinders come with a 6mm spindle that you can use using them. The 8mm spindle choices made available, that could be more desirable for drill chucks. Cast iron, cast steel, carbon steel, alloy steel, metal while others can be deburred and polished applying this machine.

ROUND TREE CARBIDE BURRS

Burrs are usually called Christmas tree carbide burrs because their sides aren’t parallel in addition to their heads have rounded ends. Since these carbide burrs are round trees, their round shape brings about suitable for profiling corner welds. Besides machining and casting parts, you can even start using these tools to shape curves in metal castings and machined components. Among the solutions on the spindle may be the extended spindle option which facilitates access to internal corners. Both hard metal spindles and solid non-ferrous spindles are most notable range. Both hard metal spindles and solid non-ferrous spindles are most notable range. Through the use of extended spindle options, it is possible to reach into corners with ease. Besides hard metals, for example stainless, non-ferrous metals, like aluminium alloys or bronze, can also be treated.

POINTED TREE CARBIDE BURRS

For general-purpose use, the tungsten carbide is manufactured in a high-quality product. You will find there’s range of carbide burrs which may have pointed tree-shaped edges. Great for deburring internal corners and neatening narrow internal tig welds. Additionally, you can also make use of them to shape curves and arcs. There are numerous sizes with this range for hard metals, such as stainless-steel and mild steel. The pointed trees of tungsten carbide burrs are generally useful for crushing and grinding the main element materials found in industrial manufacturing processes. These are suited to fine and coarse stock removal on the most frequent materials. In addition, they don’t require a specific material and still provide a good ability to stock removal. An incredibly high a higher level concentricity enables the person to work with no chatter marks even under opposites. A really high a higher level concentricity allows the user to use no chatter marks even underneath the most effective impact conditions. Through the use of the correct of tungsten carbide, geometry, and cut, you are going to achieve coating the best possible stock removal rate.

INVERTED CONE CARBIDE BURRS

While using inverted cone shape, hidden edges might be chamfered, shaped, and deburred. In our collection of tungsten carbide working heads, you can select between two designs, one with a standard spindle and something by having an extended spindle, that is a good choice for employed in areas of higher capacity. This machine can readily deburr and polish cast steel, carbon steel, alloy steel, stainless steel, as well as other materials.

WHEEL BURRS

There are a selection of tasks that can be carried out by wheel burrs, driving them to very versatile. As they are cylindrical burrs, these people have a similar profile and size to cylindrical burrs. Still, because of the very narrow edges, they are able to produce precise lines as required and grinding and shaping. This wheel has blades on both sides and the top lid for doing things vertically and clear the lining of bezels.

To read more about 1 4 die grinder bits take a look at our web page