I’m an area service engineer for food packaging machines instead of an automation specialist, however can provide you with few hints.

For many automation systems to be effective, you should first use a clear and detailed mechanical plan with all of details finalized. If you do so, you should specify the sort of motions involved, e.g.: linear or rotary. This allows you to know the number and types of motors and actuators you will need(servo, ac single phase, ac 3 phase, pneumatic actuator).

For each and every motors you may need relay contactors (for single speed discrete/on-off type motors like blower fans and liquid pumps), VFD for speed controllable ac 3-phase motors(more like conveyors, liquid tank level control pumps or rollers).Servo motors need Servo drivers to manage their precise movement.

They’re your output devices, you will want your input devices to get set out. This is level sensors, flow sensors, proximity switches along with other devices as required. The main reason i’m stating out this routine would be to let you define the specifications needed for your control system hardware requirements. All PLC manufacturers layout their product line-up depending on system complexity.

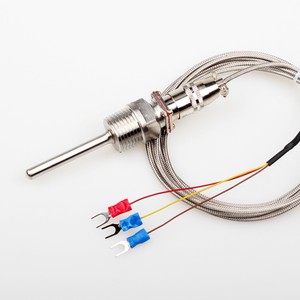

Most PLC hardware is sold as reconfigurable rack chassis. Basically you will find the CPU the master brain that’s supplemented with I/O device that could be slotted in like cards. Additional complex systems which needs servo motor will have servo card for connecting with servo driver, communication bus cards like CAN-BUS, PROFIBUS and DEVICENET and sensor cards for special sensors like RTD temperature sensors and level sensors.

So exercise you IO devices list, then have the necessary hardware and software needed. You may want additional hardware needed for for fancy touchscreen display HMI, line automation and internet-based diagnostic and asset monitoring functions. That’s the way a guy with mechanical background can approach complex automation problems.

The solutions varies depending on different manufacturer offering specifically if you use beckhoff based systems. A great way to start is to develop existing machines so that you discover the basics. Go get yourself a few catalogs from reputable manufacturers to understand industry can give. It’s my job to suggest people to go through Omron catalogues. They likewise have a no cost automation online course that can teach you the child steps needed.

You have to be able to design complete PLC systems: architecture design, hardware specfications and selection, logic narratives, logic programming, connection drawings. Everything. Perhaps all you need is additional training around the more knowledge about each piece of kit, concerning how to program or properly connect them, yet it’s not rocket science, a great mechanical engineer should probably excel with this because other engineer. The key facet of control system design is usually to understand the process you are going to control and the goals you want to achieve.